In the world of eCommerce, flexibility and efficiency in managing inventory and production processes are crucial. For businesses engaged in light manufacturing, finding an efficient solution that integrates just-in-time kitting and phase based inventory manufacturing can be a game changer. SKULabs offers an innovative approach to light manufacturing through its robust kitting functionality and support for virtual/disconnected warehouses. This guide explores how you can leverage these features to optimize your manufacturing process.

The Power of Kitting in SKULabs

Kitting involves combining multiple items or components into a single product for sale. It’s a common practice in industries like electronics, auto parts, T-shirt manufacturing and appliances, where bundled products are not only popular, but necessary to represent a finished good. SKULabs’ kitting function allows you to create kits that represent all the individual component items that make up a single product, enabling you to manage inventory more efficiently while maintaining accurate stock counts both at the kit level as well as the component items.

Creating Kits in SKULabs

With SKULabs, you can easily create kits by defining a kit as a collection of specific inventory items. This approach allows you to:

- Simplify Inventory Management: By creating kits, you can track bundled products as a single unit, reducing complexity in inventory tracking. Each kit will have its own SKU and barcode for representation. Inventory levels will be based on the amount of component items on hand that make up a single kit.

- Ensure Accurate Stock Levels: SKULabs automatically adjusts stock levels for individual components when a kit is sold, ensuring accurate inventory counts and eliminating the logistics of keeping up with the component items. Kits are calculated automatically in the background and advertised as a whole on your sales channel.

- Facilitate Order Fulfillment: Kits can be seamlessly integrated into your order processing workflow, streamlining fulfillment and reducing errors. This allows you to fulfill a group of items with a single scan of a barcode.

To create a kit, you simply name the Kit, assign a SKU and fill it with component items. SKULabs takes care of the rest, ensuring that each kit is accurately represented in your inventory system.

Virtual/Disconnected Warehouses: A New Approach to Manufacturing

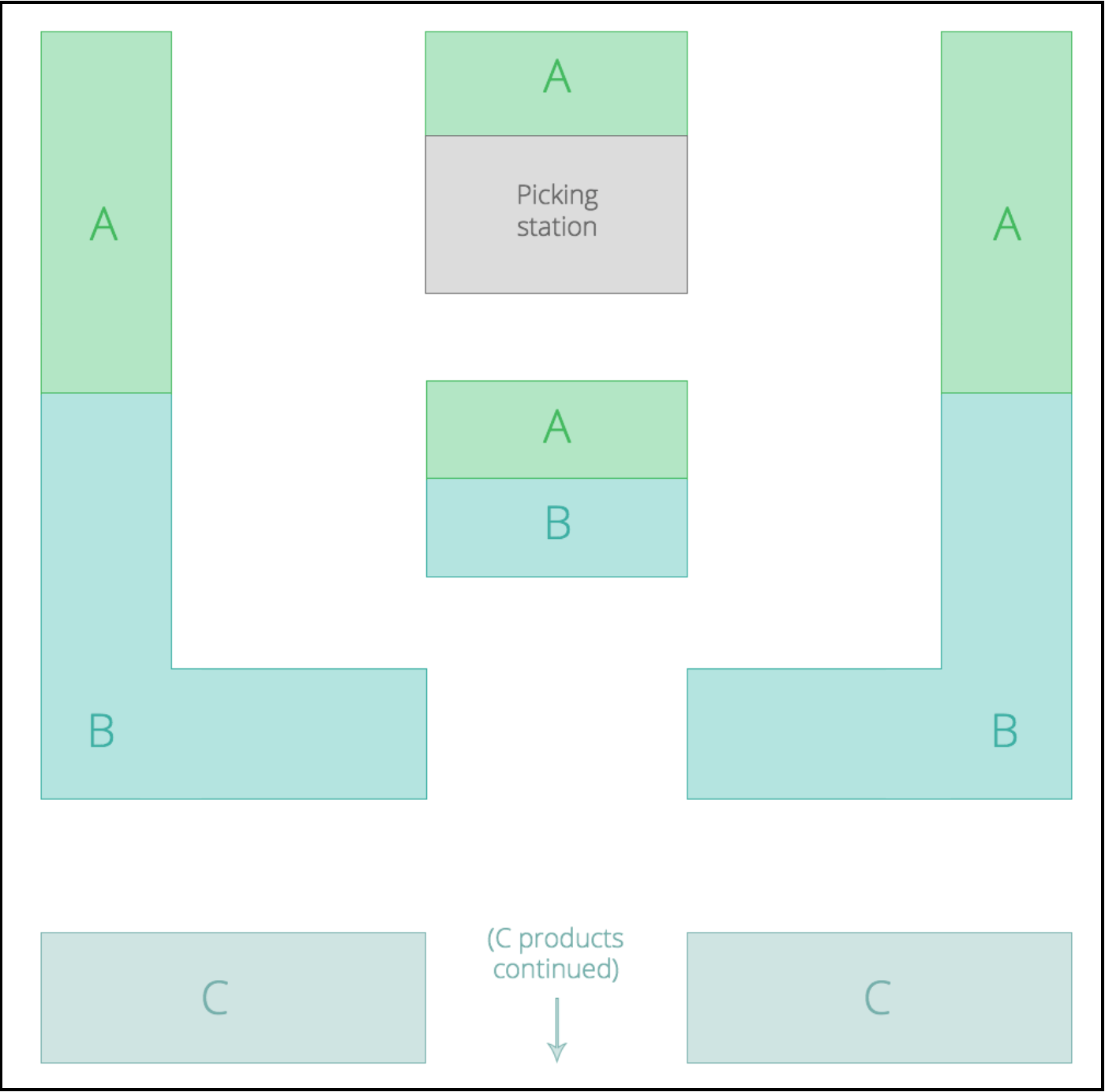

One of the unique features of SKULabs is its support for virtual/disconnected warehouses. This feature allows you to represent different stages of the manufacturing process as separate warehouses, providing greater flexibility and control. Here’s how it works:

Virtual Warehouses?

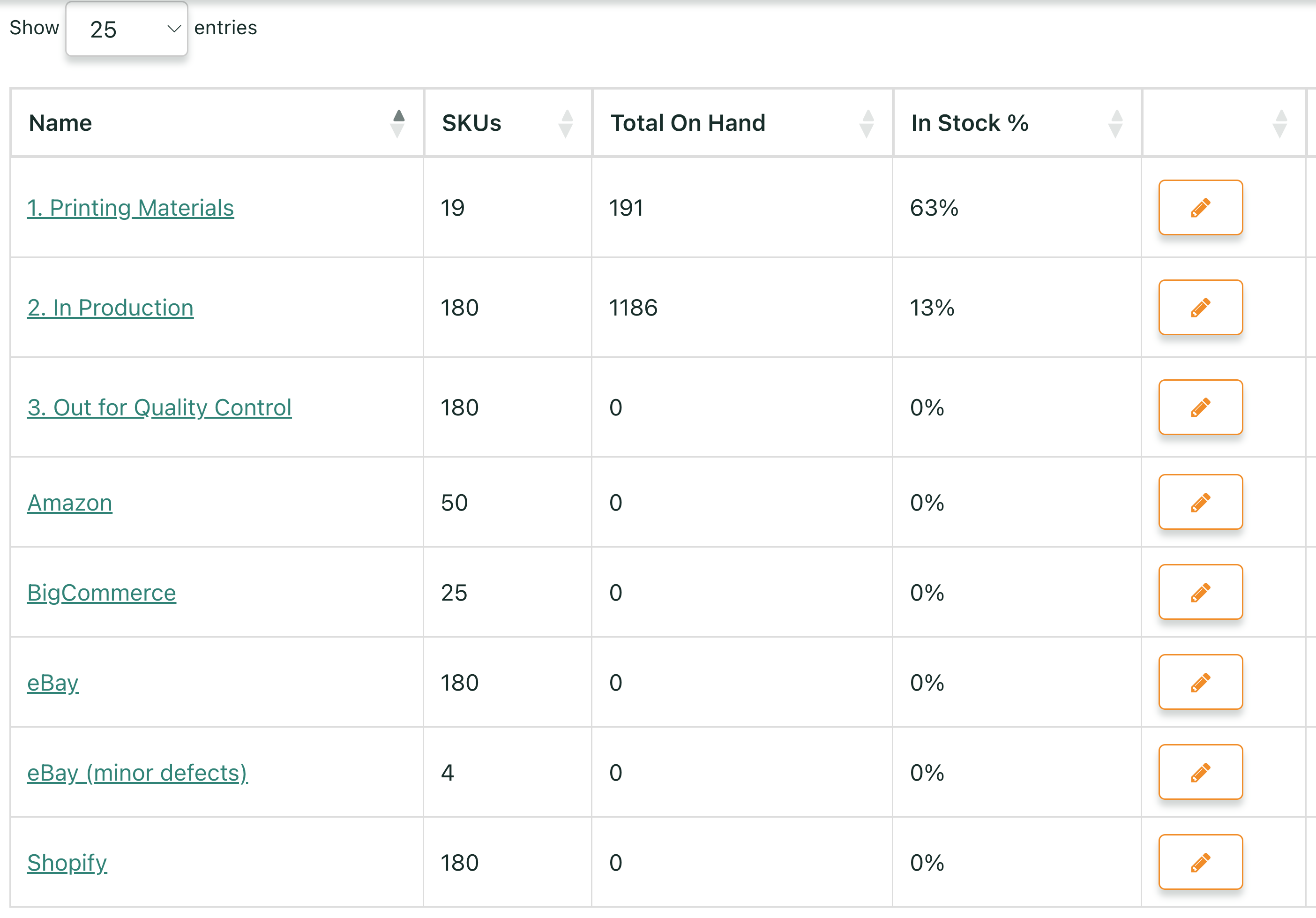

A virtual warehouse can be used as a digital representation of the different stages of production in an inventory management system. These stages may include intake and housing of raw materials, assembly of products, items sent for quality control, and ultimately advertised inventory to your sales channels. The primary advantage of using virtual warehouses is the ability to track inventory levels and the flow of goods across different stages without the need for spreadsheets or other costly softwares. With the proper setup, virtual warehouses can streamline operations, improve visibility, and boost overall efficiency.

Setting Up Disconnected Warehouses

In SKULabs, disconnected warehouses are separate inventory locations not directly tied to a specific eCommerce sales channel. This feature is ideal for representing manufacturing stages, enabling you to track the progress of your products as they move through the production process and know what is on hand. By setting up disconnected warehouses, you can:

- Define Manufacturing Stages: Create different warehouses to represent stages like “Intake”, “Assembly,” “Quality Control,” or “Packaging.”

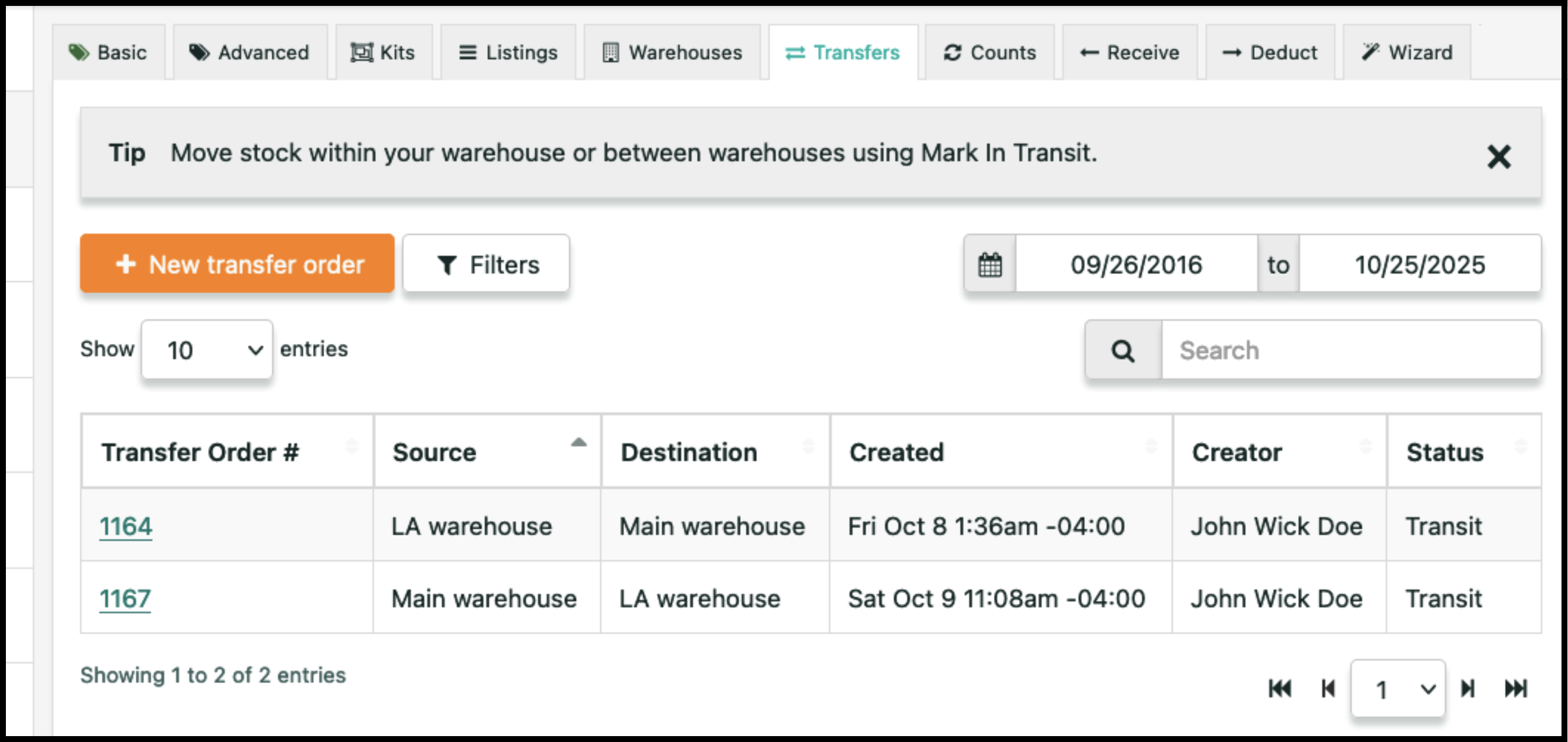

- Track Inventory Movement: Easily move inventory between warehouses to reflect the manufacturing process. This is a simple internal warehouse transfer which gives you granular control on how much stock is moved, and which phase of the process it should represent next.

- Ensure Product Readiness: Once a product is complete, you can transfer it to your connected warehouse, making it available for sale on your e-commerce platforms.

Integrating Disconnected Warehouses with Kits

The combination of kitting and disconnected warehouses allows you to represent the entire manufacturing process within SKULabs. Here’s a simplified workflow:

- Define Kits: Create kits in SKULabs that represent the finished product, specifying all the components needed for assembly.

- Set Up Disconnected Warehouses: Create warehouses for each stage of the manufacturing process.

- Move Inventory Through Stages: As components are progressing into assembled kits, transfer them from one disconnected warehouse to the next to reflect the manufacturing progress or stages.

- Complete the Product: Once the kit is fully assembled and ready for sale, transfer the components to your connected warehouse, making it available for order fulfillment.

- Fulfill Orders: With the product in your connected warehouse, you can seamlessly fulfill customer orders and manage inventory levels across your eCommerce sales channels. This method also lets you sell and keep track of your component items individually!

Running Low on component items?

Now that we have simplified the logistics for maintaining accurate inventory levels for your products that are made up of various component items, how do you keep an eye out for that one component item that will keep you from completing these assembled goods? Take advantage of SKULabs’ built in inventory alert system. Right on your SKULabs dashboard, you will maintain visibility of all of the items that have hit or fallen below your assigned threshold of on-hand counts. Not always in front of your app or device? No problem, we can automate these stock alerts to be sent to your desired email address to keep you in-the-know while on-the-go!

Keep it Simple

SKULabs offers a comprehensive solution for light manufacturing by combining kitting functionality with the flexibility of virtual/disconnected warehouses. By utilizing these features, you can efficiently manage the production process, track inventory accurately, and ensure a smooth transition from manufacturing to order fulfillment. Whether you’re a small business or a larger eCommerce operation, SKULabs provides the tools to streamline your light manufacturing process and keep your customers satisfied!

Connect with SKULabs Today

Now is the perfect time to discuss how we can help you get prepared for taking your business to the next level!

Chat with one of our experts today. Schedule a meeting or give us a call at 1800-243-2986 to learn more.