Your warehouse is arguably your most valuable business asset. This is where your goods come in and orders go out, and the speed and efficiency in which these things happen is vital to your success. It makes sense, then, that you may be concerned about warehouse organization. Keeping this priceless asset tuned can make a huge difference in how your business runs. Let’s go over a few ways that you can take your warehouse organization to the next level:

1. Label locations and boxes

If you haven’t done so already, labeling where you store each SKU in your inventory is critical. All it takes is a simple sticker with a name and a barcode to make a huge difference in how your team works with inventory. Now, instead of having to train and memorize where everything is kept, all of the SKU picking and storage locations can be quickly referenced. Implement barcode scanning to add to your team’s picking and counting efficiency – all it takes is a quick scan to verify the SKU you’re handling.

2. Keep aisles clear

Few things hamper productivity in a warehouse more than having to navigate around loose boxes or pallets in the aisles. The time spent keeping your walkways clear will pay dividends by allowing your team to quickly and safely navigate through your warehouse. Preventing clutter from building up also ensures that inventory makes it to the correct location, rather than being placed somewhere else due to a lack of access.

3. Rack your pallets

When you’re thinking about optimal warehouse organization, think vertically. The average warehouse storage interior is at least 21 feet tall. In a 20,000 square foot warehouse, that’s over 420,000 cubic feet of potential storage! Make the most of your space by storing pallets of inventory on pallet racks. These are cost-effective, easy to assemble storage solutions that give you direct access to each pallet. You can also store loose inventory in the space below the racks so your team can make use of all of your warehouse space on foot.

4. Use ABC grouping

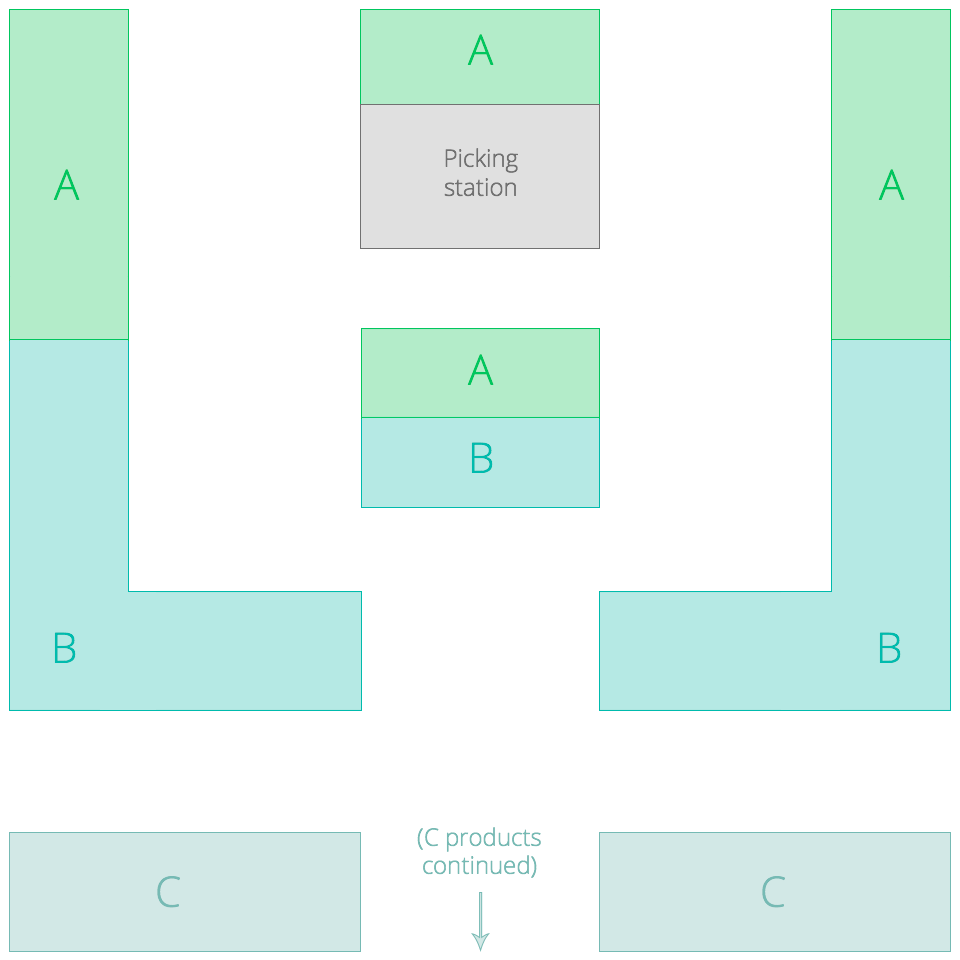

E-commerce retailers can very likely identify a small portion of their inventory that is more frequently picked and shipped than the rest. These golden tickets to profit are being shipped more often, and need to be in stock more consistently, than the vast majority of the remaining catalog. To make picking and counting these items easier (especially when using cycle counting), group your inventory into three categories: A for your top sellers, B for your above-average sellers, and C for your below-average sellers. Then, arrange your picking floor so that your team has the easiest access to A SKUs, then B SKUs, and finally C SKUs. Here’s one example layout that illustrates smart use of ABC grouping:

5. Use the Pareto principal

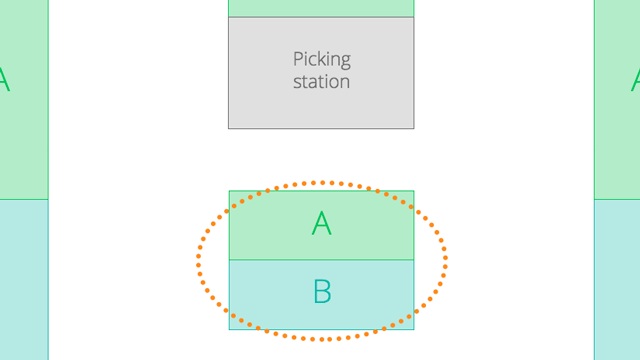

We’ve all heard different variations of the 80-20 rule. 20% of fishermen catch 80% of the fish. 20% of companies hold 80% of the wealth. More importantly, 20% of your SKUs can likely be found in about 80% of your orders. This phenomenon is called the Pareto principal. Use this concept to your advantage and group that 20% of your catalog closest to your main order picking area. Note the image above employing ABC grouping and see where you might put your Pareto products. For example, you could use that center-most storage space that’s being shared between A and B SKUs:

These simple optimizations can reduce workers’ travel time to complete tasks, increase order fulfillment output, reduce picking and counting errors, and save you thousands of dollars. Have any other ideas for warehouse organization? Let us know in the comments below, or share your tips on our forum.