The Challenge of Multi-Channel Inventory Management

Selling on multiple platforms, like Shopify, Amazon, eBay, and others, can be highly profitable, but also introduces some unique challenges. Each platform has its own inventory system, and without the right tools, keeping them all synchronized manually, avoiding overselling, and ensuring a seamless customer experience can be a logistical nightmare. Sure, you could spend your whole day tracking spreadsheets, signing in to each store, and updating inventory by hand. You might even finish with some spare time left to worry if anything has changed since you first started…but is this really the best option?

“Trochees, what are trochees?”

George Frideric Handel

Where SKULabs takes the stage

With the pace of online ecommerce growing faster by the day, seconds are what can make the difference between another successful sale or a cancelled order. Inventory changes need to be quick, efficient, and automatic, no matter how many orders or sales channels you are managing.

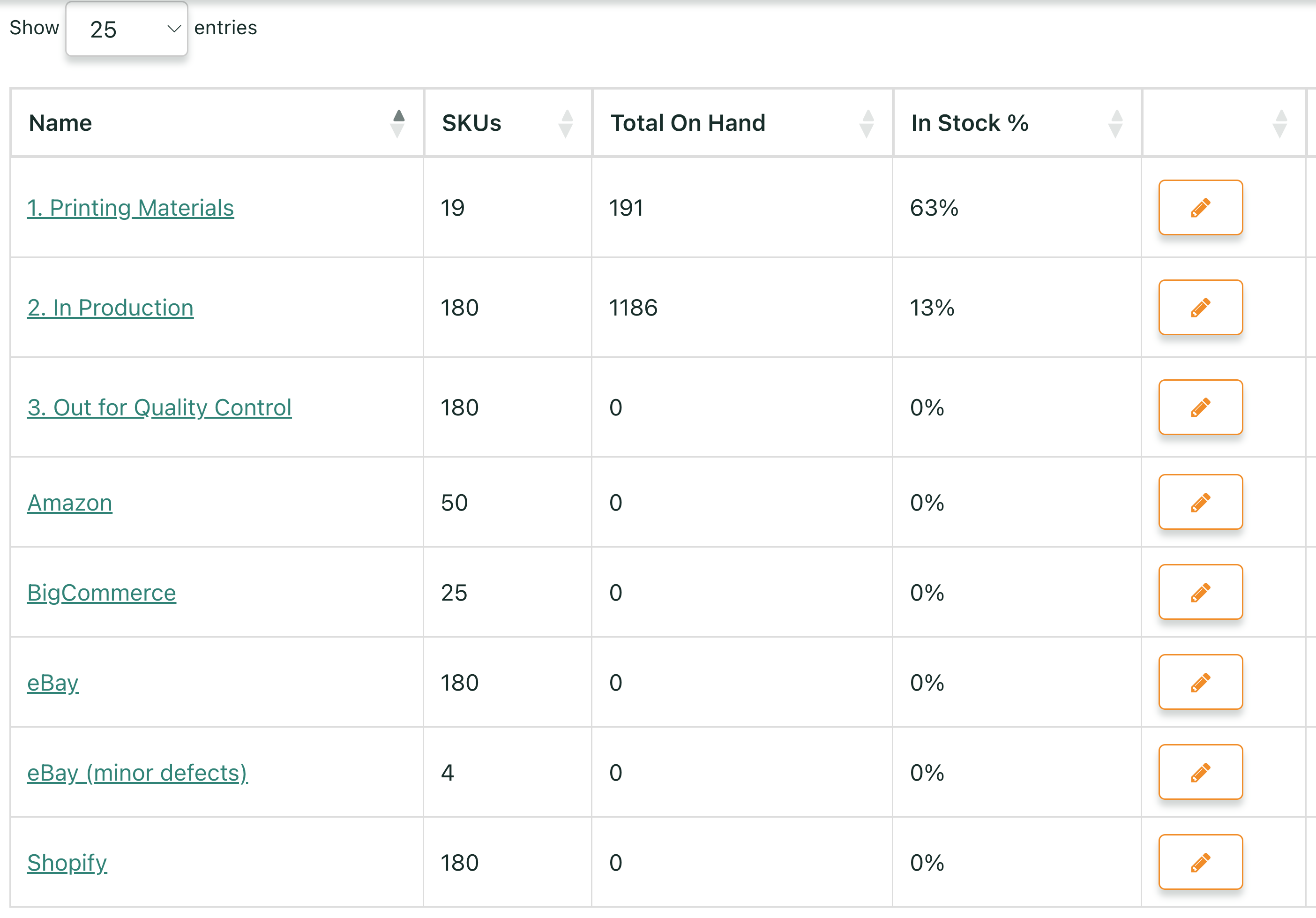

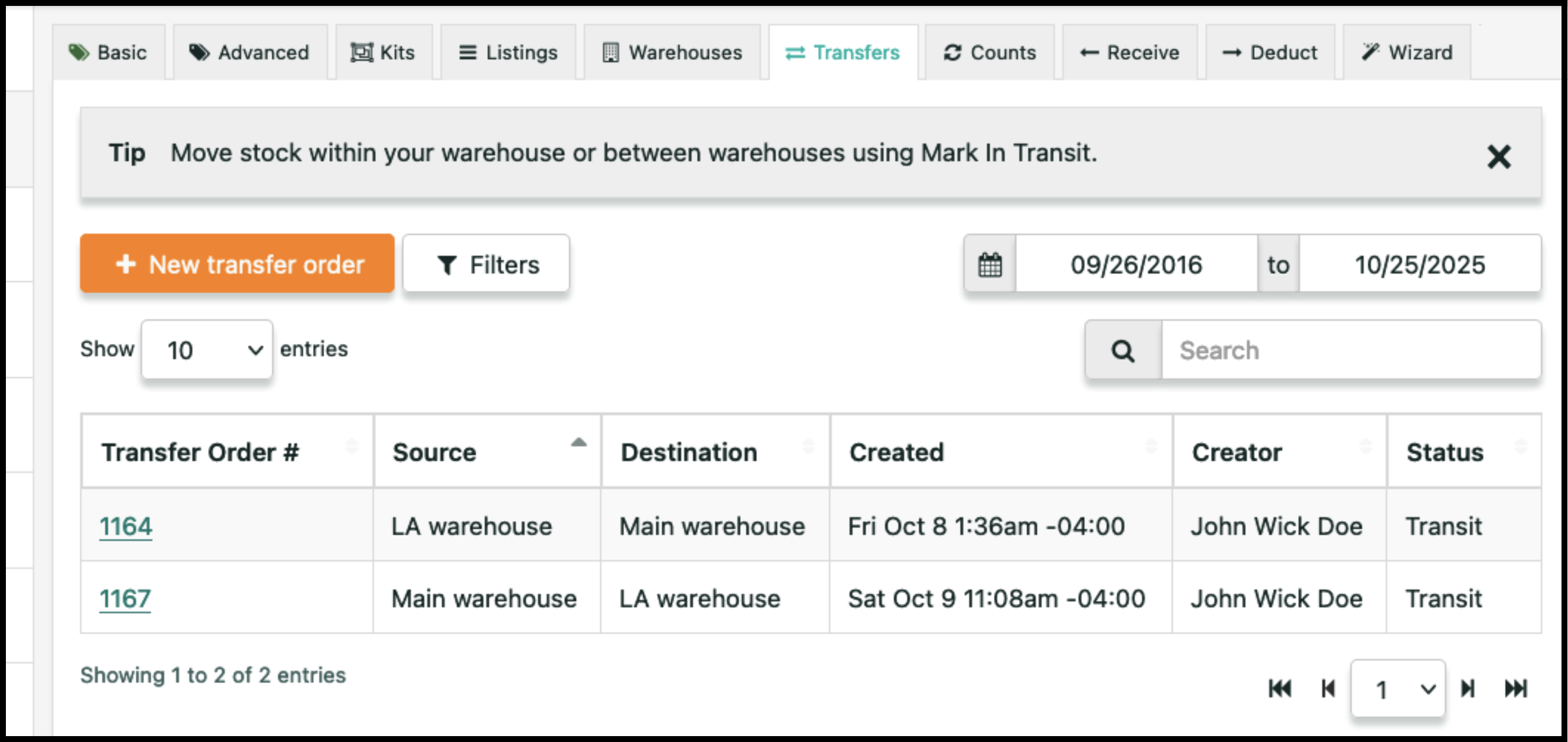

While SKULabs offers a wide array of features, our biggest focus is providing solutions as a multi-channel inventory management tool. We help ensure inventory remains accurate across multiple stores and sales channels with real time inventory updates and customizable stock rule strategies, reducing your risk of overselling and giving you more control over how you sell. This essentially automates what would normally require the cost and effort from a full time position! Instead of being overwhelmed with managing stock from your individual sales channels, each store works in concert with one another to help your entire business perform better overall.

Real time updates reduce the odds of overselling

Having real time data on inventory levels is the key to making best informed decisions and avoiding discrepancies across sales channels. Every order placed is reflected upon inventory levels within SKULabs and the stock advertised on your channels. When an item is sold on Shopify, your stock in Ebay will be adjusted. When you’re ready to place a purchase order, you can consider sales from all your channels at once to meet your reordering needs.

Customizable stock rules help you sell faster with better control

Want to hold 5 units back for safety stock, exchanges, or replacements? No problem. Want to advertise inventory for a pre-sale period? Consider it Handel’d. SKULabs offers powerful and fully customizable stock rules that give you complete control and peace of mind over how inventory is tailored to pushed to each of your sales channels. These rules can be applied at both the channel level and the individual listing level, providing you with granular control over your inventory. Here are some ways you can use stock rules to optimize your inventory management:

- Channel-Level Rules: Set different stock rules for each sales channel. For example, you might want to reserve a certain amount of stock for a specific channel to meet demand or maintain a buffer.

- Individual Listing Rules: Customize stock rules for individual products. This is useful if you have high-demand products or items with limited availability. Or even for those you want to skip pushing stock for altogether.

SKULabs vs. Manual Inventory Management

Managing inventory across multiple channels manually or with spreadsheets is not only time-consuming but also risky. Errors in stock levels can lead to overselling, missed sales opportunities, and a poor customer experience. SKULabs provides a far better solution by offering:

- Automation: Real-time updates and stock rules automate much of the inventory management process, reducing the need for manual intervention.

- Accuracy: With all your inventory in sync, you can be confident that stock levels are accurate across all sales channels.

- Scalability: As your business grows and you add more sales channels, SKULabs scales with you, providing a unified solution for managing inventory.

Conclusion

Real-time inventory updates from SKULabs offer a comprehensive solution for managing inventory across multiple ecommerce sales channels. By reducing the risk of overselling, providing powerful customization options with stock rules, and automating key processes, SKULabs can help you streamline your inventory management and focus on growing your business. Say goodbye to the headaches and time spent on maintaining inventory across sales channels, and take your inventory management to the next stage. Your customers—and your bottom line—will thank you.

🚀 Connect with SKULabs Today

SKULabs is used as an all-in-one solution or integrated with existing inventory management software across all sizes and all different types of operations to maintain line of sight to all inventory at all times and reduce picking, packing, and fulfillment errors.

- Real-time Synchronization: Never over-sell or under-stock again. Our software provides near instant synchronization across all your sales channels.

- Quick Setup: With SKULabs, you could be up and running in as little as 30 minutes to 10 working days for a comprehensive setup based on your unique operations.

- Top-tier Integration: Whether you’re on Shopify, Amazon FBM/FBA, or any other leading eCommerce platform, we’ve got you covered.

- No hidden setup or onboarding fees – Work with our account managers to help you get set up at every step of the way. Free of cost!

- Unparalleled customer support – Our top tiered support team is highly praised in our reviews.

- 30-day Money-back Guarantee: Confident in our solution, we offer a no-strings-attached, 30-day guarantee. Experience SKULabs and if it’s not the right fit, no worries!

Now is the perfect time to chat with one of our experts today. Schedule a meeting or give us a call at +1 800-243-2986 to learn more about how we can help you get prepared for taking your business to the next level!