Committing to long term contracts is outdated and should be left in the past. Navigating the winding roads of inventory management and order fulfillment software can already be daunting, especially when hidden costs and pricing gymnastics are part of the equation. How many times have you found a promising solution only to be blindsided by contracts or mysterious fees tucked away in the fine print?

Or maybe you’ve endured lengthy sales pitches without ever hearing the “one number” you’re genuinely interested in…”The price”. Encountering hidden fees, and being forced to sign long term contracts can be frustrating when searching for the right inventory management software. You deserve options and above all an exit strategy if you find something does not work for you. Red flags should be thrown any time you find a software company requiring long term contracts. This is a clear indication that they are having trouble keeping their customers happy.

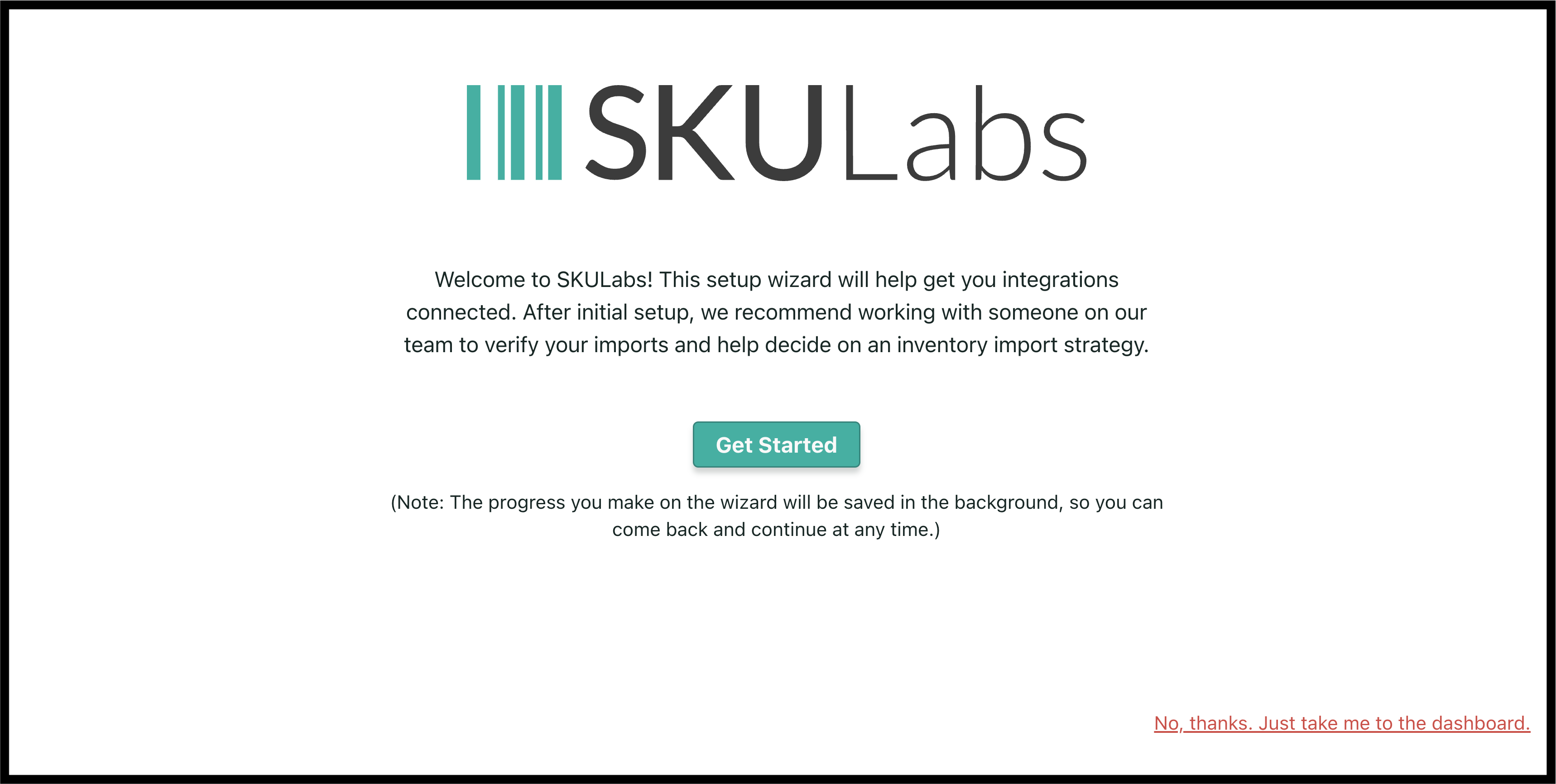

At SKULabs, we understand this frustration. That’s why we’ve rolled out new pricing plans and packages on our website, where you can see and choose a plan that best fits your needs. Free from long term commitments. We are firm believers in month-to-month contracts, giving our customers peace of mind as well as confidence in knowing we have to earn their business every month. After all, isn’t it liberating to know upfront how much you’ll be investing, free of smoke and mirrors?

Let’s dive into transparent pricing in inventory management and order fulfillment software and how SKULabs is setting an example with simple, clear pricing free if any long term contracts and a 30 day money back guarantee!

Never Get Locked into Lengthy Long Term Contracts

Why do most consumers prefer month to month contracts vs yearly commitments? Lets take a look at the top 5 reasons:

- Flexibility: Month-to-month subscriptions offer consumers the flexibility to cancel or change their subscription without a long-term commitment. This flexibility is particularly appealing in uncertain economic times or when personal circumstances change.

- Lower Initial Cost: Yearly contracts often require a larger upfront payment compared to monthly subscriptions. For consumers on a budget, spreading out payments on a monthly basis can be more manageable and less financially burdensome.

- Ability to Test Services: Monthly subscriptions allow consumers to test the service or product with a lower financial risk before committing to a longer-term contract. This trial period helps consumers assess whether the subscription meets their needs and expectations.

- Avoidance of Lock-in: Yearly contracts typically lock consumers into a commitment for an extended period. Some consumers prefer to avoid this long-term commitment and prefer the option to opt-out or switch to a different software if they find a better alternative.

- Control: Month-to-month subscriptions give consumers an amount of control over their spending and subscriptions. They can easily adjust their subscription status based on their current usage or satisfaction with the service without feeling trapped in a contract.

Overall, these factors contribute to the popularity of month-to-month subscriptions as they cater to consumer preferences for flexibility, financial control, and reduced commitment risk.

The Problem with Non-Transparent Pricing

You’re probably familiar with the hurdles and frustration of hidden fees and non-transparent pricing. Imagine finding an eCommerce solution that seems perfect for your needs, only to realize later that the advertised price doesn’t cover all the onboarding costs or even worse, you have already paid for a year of service.

There might be setup fees, service charges, or even additional costs for vital features that aren’t included in the base price. It’s like a betrayal, isn’t it? This lack of transparency can leave you feeling misled and unsatisfied.

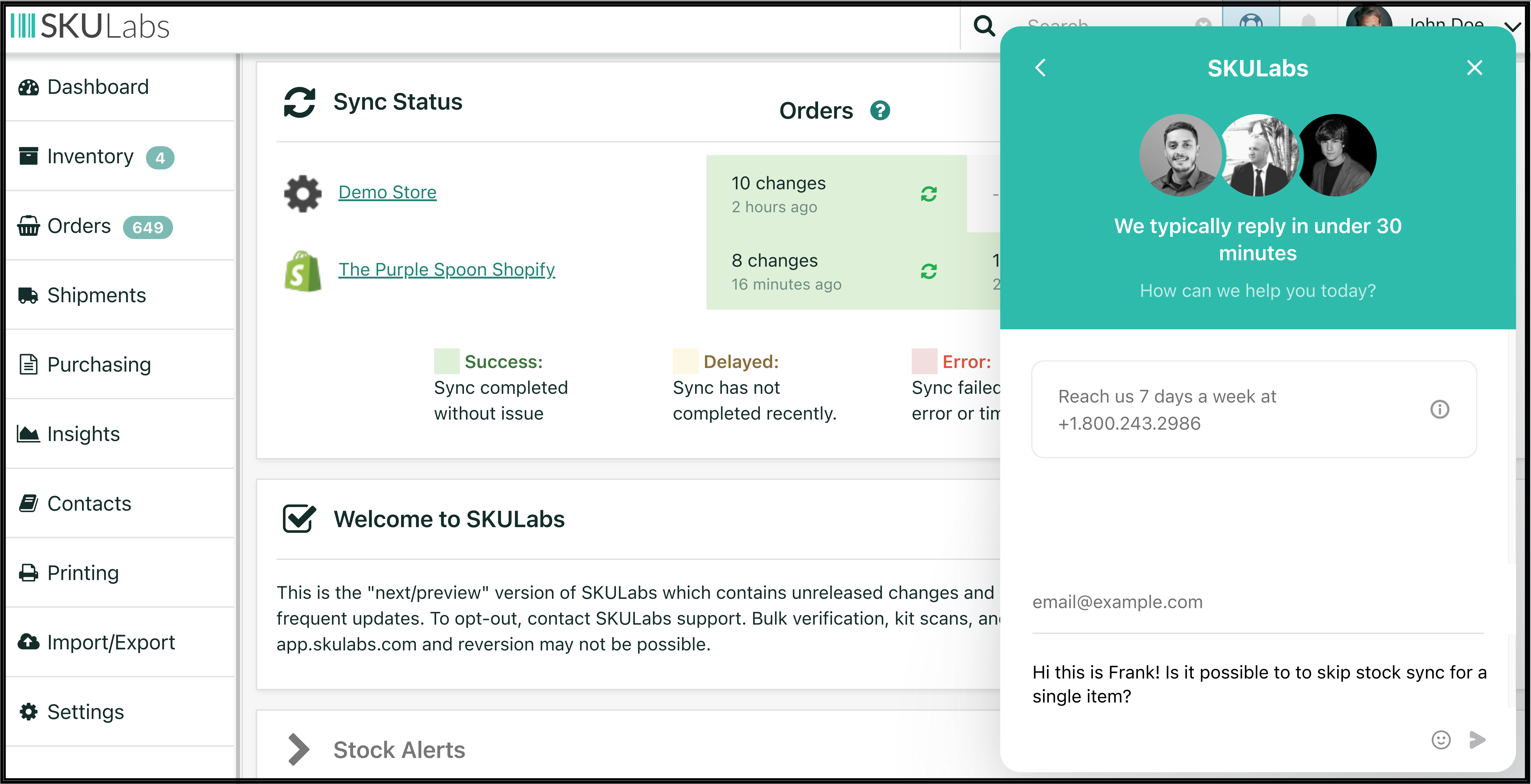

Another common issue is the high-pressure sales pitches that commonly occur on your first phone call. The anticipation of waiting to know what the service will cost you can be agonizing. The time-consuming process can frustrate you, as it’s better to know whether a service fits your budget before delving deeper into sales negotiations. SKULabs understands the importance of your time and will reserve your first phone call to answer questions to ensure all of your needs can be met without the stress of high-pressure sales.

A murky pricing model can pose serious challenges, especially if you’re running a startup. At the beginning of your business journey, you’re usually working within a tight budget.

Not knowing the full price upfront can make your budget planning daunting. As a result, you might encounter problems like financial overcommitments or the underutilization of valuable tools and services due to the fear of hidden costs. Moreover, the time and energy spent on unraveling complex pricing structures and negotiating with sales teams could be better spent on pivotal activities like product development or customer acquisition.

Our Solution: Transparent and Customizable Pricing

At SKULabs, we understand the headaches that unclear pricing models can cause, and that’s why we’ve taken a different approach. We’ve rolled out new, transparent pricing plans that put you in the driver’s seat.

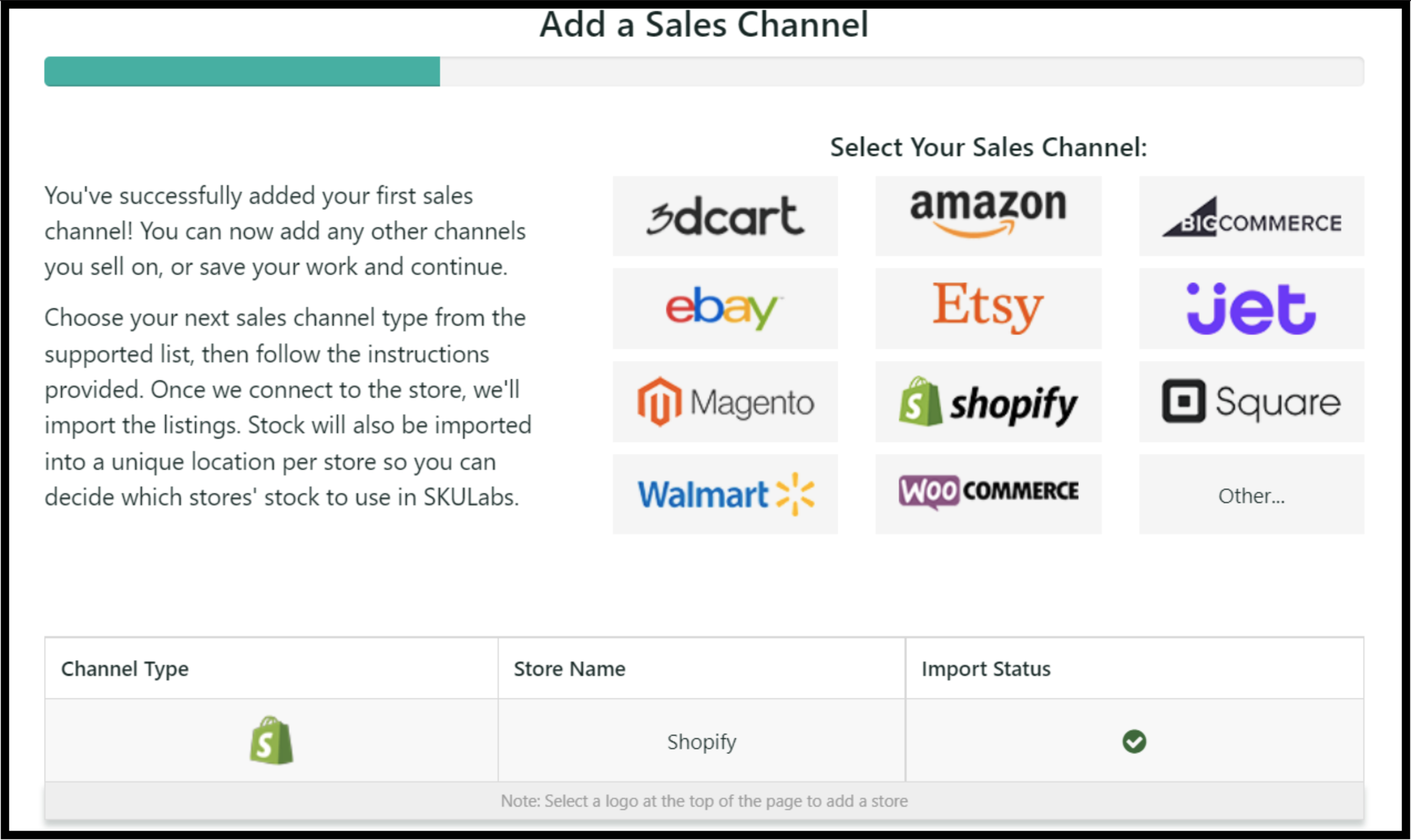

Our plans are easy to understand and customizable to fit your unique needs. Whether you’re a small startup or a large enterprise, you can choose a base plan and tweak it to suit your business requirements. This transparency in pricing brings various benefits for both you and us.

For you, it means no unpleasant surprises or hidden costs. You know exactly what you’re getting and how much it will cost, removing the guesswork and allowing you to make informed decisions.

For us, it builds trust and long-term relationships with our customers. While others may make you jump through hoops to get a price, we believe in making it easy to understand exactly what you’ll be paying. Our new pricing plans are our commitment to providing a fair, straightforward, and customer-centric experience.

Overview of Our Pricing Plans

At SKULabs, we have various pricing packages targeting businesses of all sizes. We have a plan that suits you if you’re just starting and trying to build your business. We all have packages for large enterprises that are established on online marketplaces.

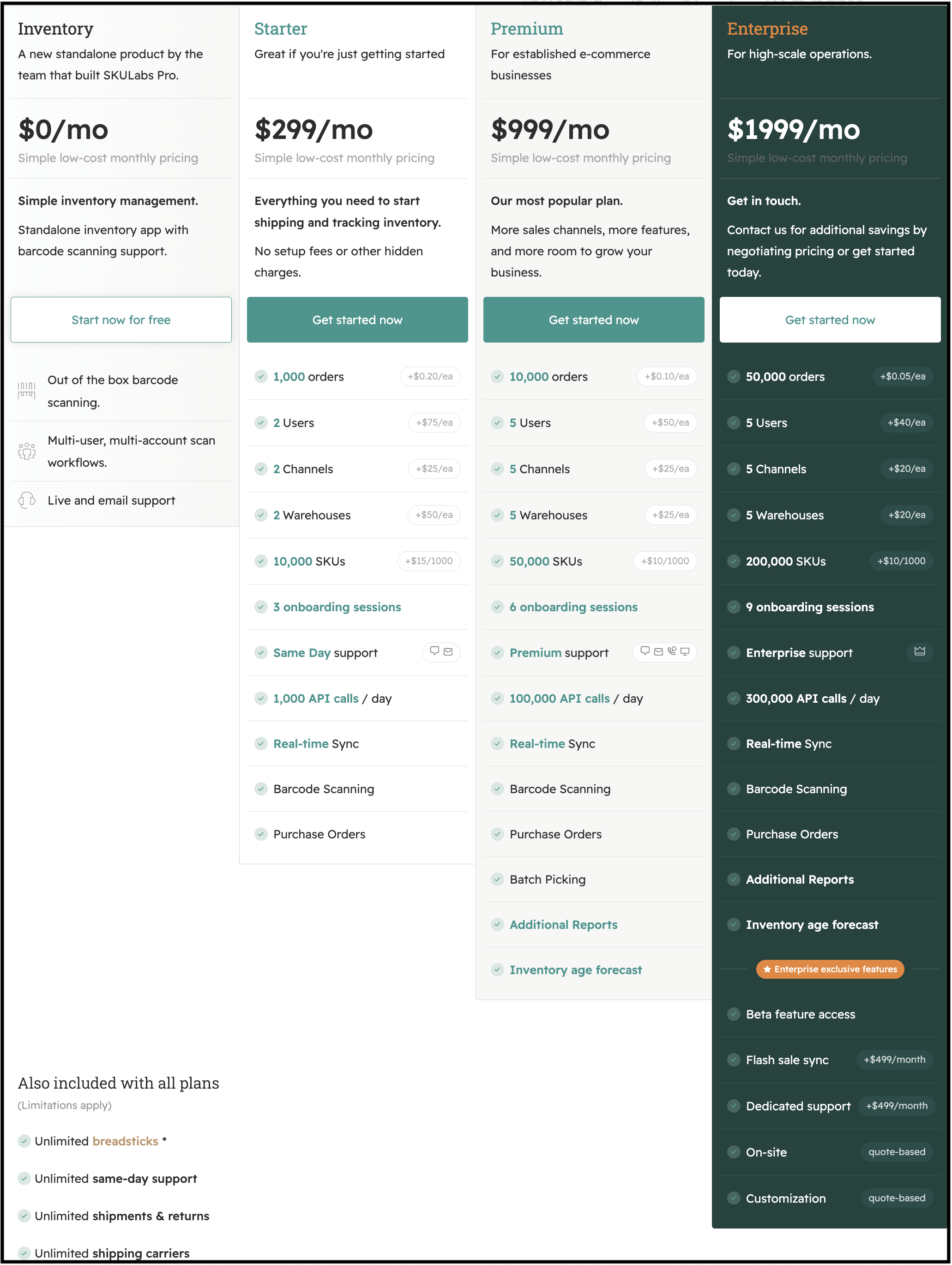

Here is an overview of our plans and pricing to help you find one that suits your business needs:

The Starter Package

This basic package is designed to make inventory management more affordable for small businesses trying to grow their operations. It costs $299 per month and gives you access to everything you need to start shipping and tracking your inventory.

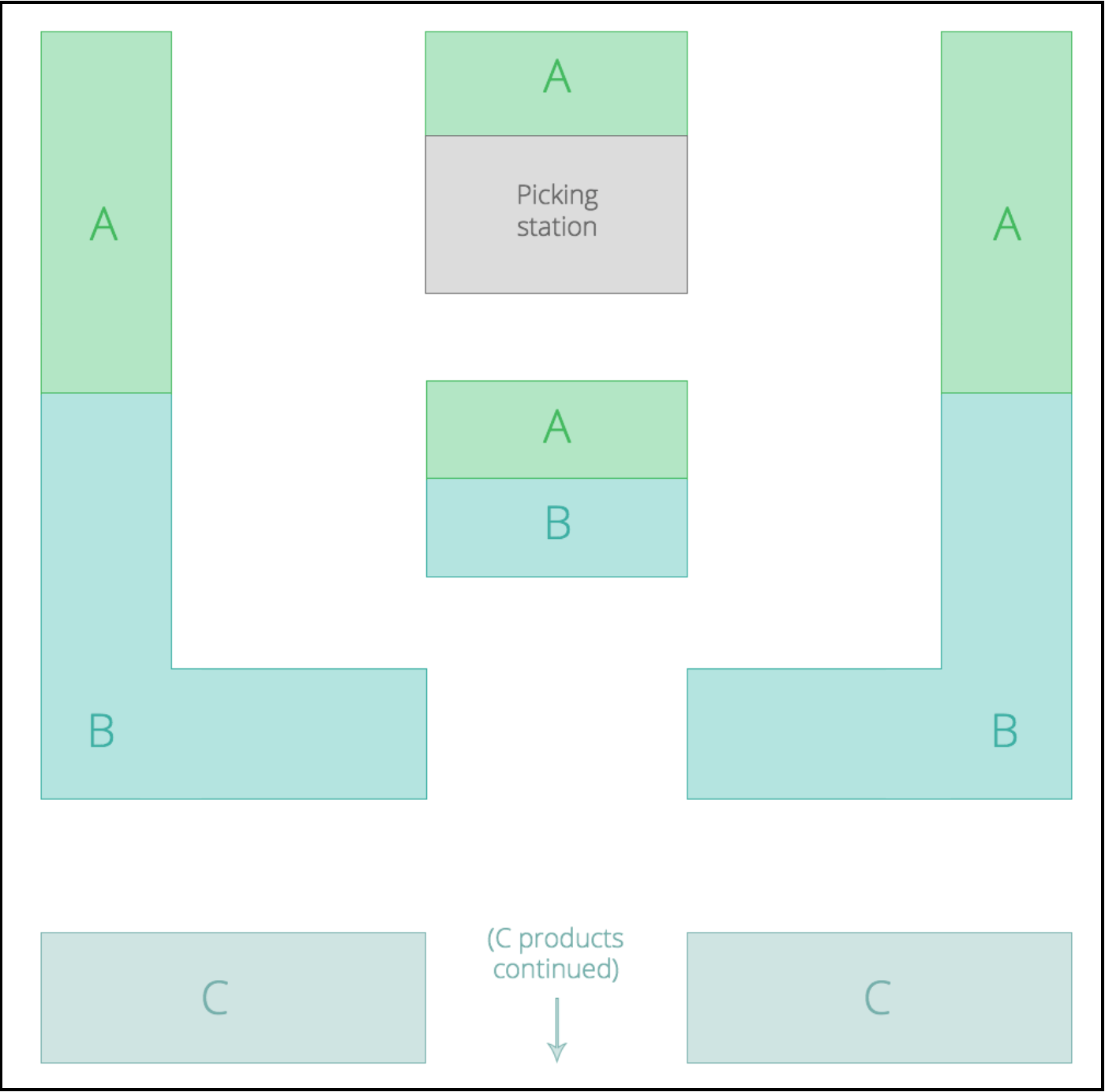

The basic package supports up to 1,000 orders and charges $0.20 for each additional order. It also supports two users and two stores, charging $75 for each added user and $25 for every added store. You’ll enjoy real-time sync for multi-channel inventory management, access to purchase orders, shipping carriers, barcode scanning, and 10,000 SKUs.

The Premium Package

This is our most popular plan, going for $999 per month. The higher price means access to more features and sales channels, creating a better opportunity to grow your business. For instance, the cap for orders is 10,000, and the plan supports five users and five stores.

The Pro package gives you access to all the features in the basic plan and more. For instance, the plan allows for batch picking and gives you detailed insights to help you improve your inventory management. You will also get inventory age and forecasts to maintain optimal stock levels, reducing overstocking and stockouts.

The Enterprise Package

The Enterprise Plan is our premium offering going at $1,999 per month. It’s designed for businesses that need a more customized solution and larger businesses that need high-volume handling. The Enterprise Plan includes all the features of the Pro Plan but is designed to handle even more orders, up to 50,000.

One of the notable features of the Enterprise pricing plan is the optimized sync, ensuring your inventory, sales, and order data across multiple sales channels and warehouses are always up-to-date. You’ll also get dedicated support from the SKULabs team.

The Enterprise Plan also allows flash sale sync to help you handle sudden spikes in demand effectively during flash sales or promotional periods. Other features include custom reports and access to beta features, allowing you to try out and benefit from the latest innovations from SKULabs before they are released to all users.

Discover the Freedom of Transparent Pricing with SKULabs

In a world where long term contracts, hidden fees, and non-transparent pricing run rampant, SKULabs stands out as a breath of fresh air. Our new transparent pricing plans put you in control, empowering you to make informed decisions without any surprises. Whether you’re a small startup or a large enterprise, we have a plan tailored to your needs. With a clear pricing plan, you can choose a plan that streamlines your inventory management and order fulfillment without straining your budget. Get started with SKULabs today to say goodbye to pricing gymnastics and embrace a new era of simplicity and trust.

Or give us a call at 1800-243-2986 to speak with an onboarding specialist today!