Using barcode scanners in SKULabs can significantly enhance the efficiency, accuracy, and reliability of your inventory management and order fulfillment processes. Barcode scanners streamline product identification and tracking, enabling quick and error-free data entry. This reduces the likelihood of manual errors in inventory counts, which can help avoid overstocks or stock-outs and ensure that the right product is always picked and placed into the correct bin. Also, by automating tasks, barcode scanners can improve operational speed and productivity, saving the staff valuable time that can be devoted to more strategic activities. Additionally, they enable real-time inventory updates, providing accurate visibility into stock levels and helping businesses make more informed decisions. All these benefits ultimately contribute to improved customer satisfaction, as order accuracy and timely deliveries are key to eCommerce. Check out our previous blog to see why barcode scanning is a great option in SKULabs!

What are Barcodes?

In simple terms, a barcode is an image form of numbers and text that represent product data. That image can be scanned with a handheld mobile scanner device and accessed into an inventory management system in real-time. In warehouse management, barcodes represent unique items in inventory and are created for identification.

Why use Barcodes?

As inventory levels and sales grow the ability to manage items by hand or spreadsheet can become cumbersome and prone to human error. Full inventories or cycle counting can become painfully inaccurate and take an unnecessary amount of time that could be utilized on more productive fulfillment tasks. In the time it would take to manually type a few characters, dozens of items could be barcode scanned with a higher accuracy level.

Many businesses utilize barcoding to not only efficiently automate inventory counting, but to also optimize their fulfillment processes while picking, packing and shipping orders.

Types of Barcodes

Barcodes can come in many different types of formats, referred to as symbologies. The symbology will determine the number of characters it can include, and what specific set of characters it can display. Codes like UPC-A (12 digits) or EAN-13 (13 digits) are widely used in retail, and you’ll often see Code 128 (which can display all 128 ASCII characters) represent the tracking codes on packages.

How to Create Barcodes

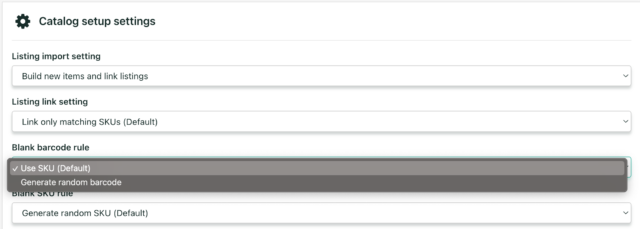

In SKULabs every item requires an assigned SKU and barcode. Very often customers have their own SKU created in a format that provides necessary details about an item for a basic identification. A barcode could be a duplicate of the SKU or it could be a completely separate product code such as a UPC, GTIN, or other internal identification code.

What if I don’t have any barcodes on my items? An excellent tool for getting started creating barcodes is with a barcode generator. SKULabs is able to convert your SKU into a barcode or we can automatically generate them when importing from your sales channel.

Additionally, many websites provide automated barcode generators (both paid and free). Some have more product identification type features than others so take a look around and find the one that fits your inventory needs.

SKULabs utilizes Code-128, which can represent all 128 ASCII code characters (numbers, upper case/lower case letters, symbols and control codes). This allows SKULabs to read most barcode types.

- Here is an example of a free barcode generator website tool. This tool enables you to select a linear code such as Code-128. It has some basic configurable sequence tools for prefix, suffix, start value, etc. There is no right and wrong with these settings, they need to be set for what works in helping to identify items.

How to print Barcodes

A standard laser printer or a dedicated label printer can do the job. SKULabs provides a label printing utility to print on most standard size labels that can be purchased Online or at your local office supply store.

Barcode Scanners

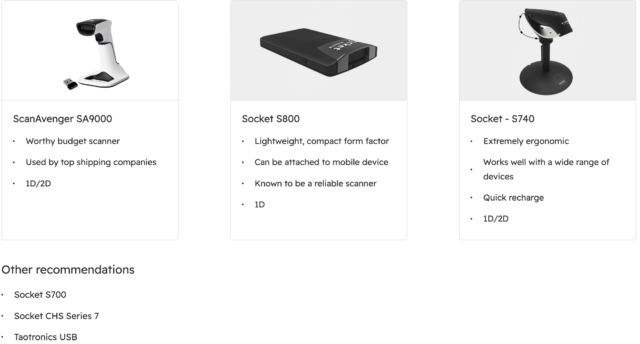

Depending on the needs/goals of your warehouse fulfillment process there are different types of barcode scanners to choose from. USB and bluetooth wireless scanners each have unique advantages that benefit specific warehouse processes. Have a look here at our recommended hardware page.

- Wireless Scanner

Wireless barcode scanning can be beneficial to larger warehouses in enabling untethered traveling while picking items. A bluetooth barcode scanner enables the operator to do business as far as 10 meters away form the device. If using a connection to a smartphone or tablet, they can go anywhere in the warehouse. Wireless scanners depend on batteries which creates a small amount of regular maintenance needed. Bluetooth scanners generally are more expensive than USB scanners. - USB Scanner

A USB scanner may be an optimal solution if items in a warehouse are brought to a central location for scan verification and packing. USB scanners often are less expensive than bluetooth, and offer convenient, fast, & secure connections. Since USB connections require a plug and cord, they are limited to wherever they can be plugged in, however battery life is not a factor.

Over 99% of barcode scanners support an “HID” compatibility, “Basic”, or “HID Mode”, which simply uses the scanner as a keyboard, so most USB or bluetooth barcode scanners work just fine with SKULabs–regardless of whether you’re on a desktop or mobile device.

Is SKULabs the right software for your business needs?

- Accurate inventory tracking and synchronizing across channels

- Efficient order picking and faster shipping

- Eliminate fulfillment errors using barcode scanning or manual verification

Connect with SKULabs Today

Now is the perfect time to discuss how we can help you set up your barcode scanners to increase accuracy and significantly speed up your picking and packing process.

Chat with one of our experts today.Schedule a meeting or give us a call at 1800-243-2986 to learn more.