Capitalizing on the most effective warehouse logistics and running a successful eCommerce warehouse operation can be a challenging endeavor, especially when faced with common problems that can hinder efficiency, safety, and profitability. However, with the right strategies and solutions, these issues can be addressed effectively. Here are the top five most common warehouse problems and how to eliminate them:

1. Inefficient Space Utilization

Problem: Many warehouses struggle with maximizing their space. Poor layout and organization can lead to cluttered aisles, misplaced items, and underused areas, all of which reduce the overall efficiency of operations.

Solution: Implement a strategic warehouse layout that maximizes the use of vertical and horizontal space. Consider using taller storage units and the right shelving systems to accommodate more items. Additionally, optimize picking locations using location naming conventions. Regularly review and adjust the layout to adapt to inventory changes. Employing warehouse management systems (WMS) such as SKULabs, can also help track and optimize space usage.

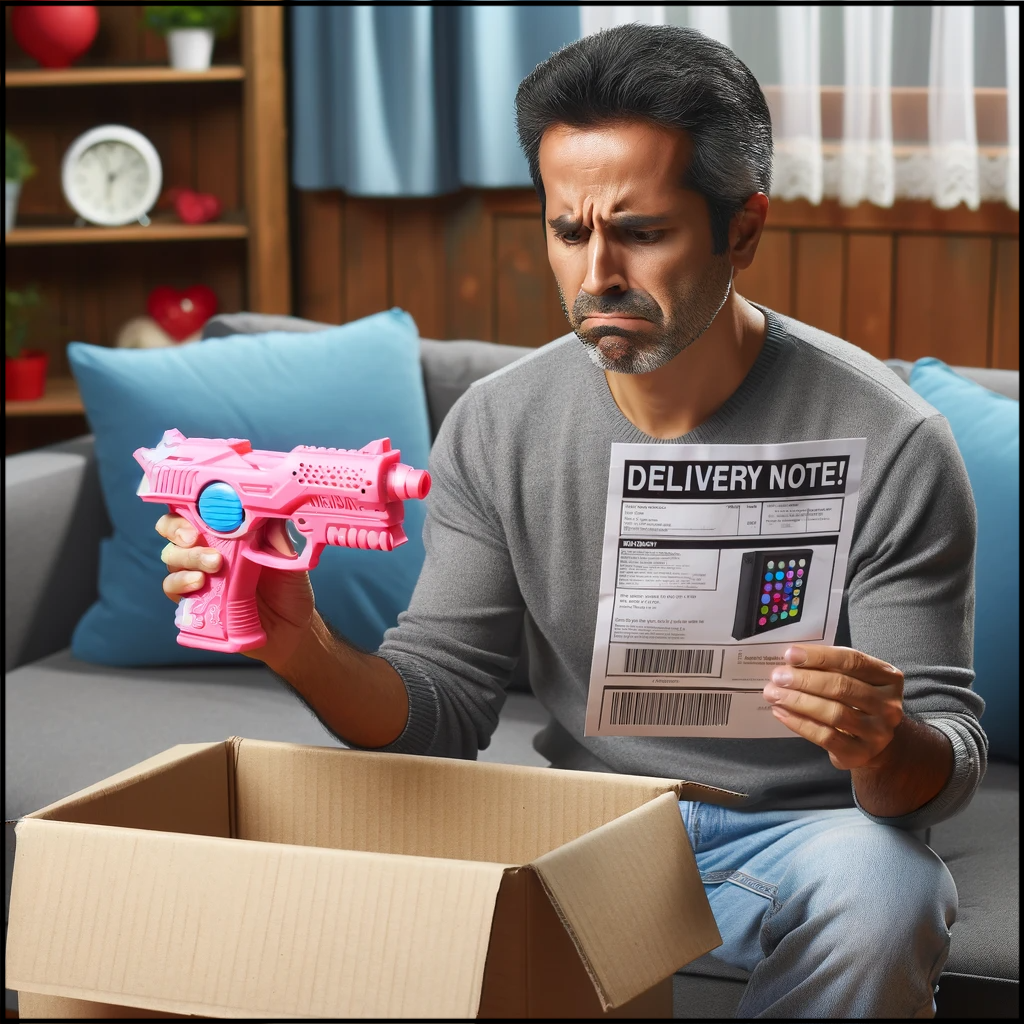

2. Inventory Inaccuracy

Problem: Mismanaged inventory can lead to several issues, such as stockouts, overstocking, and financial discrepancies. Manual processes and human errors often contribute to this problem, affecting customer satisfaction and operational efficiency.

Solution: Adopt automated systems like barcode scanners for accurate, real-time inventory tracking. Regular audits and cycle counts can also help maintain accuracy. A robust WMS can streamline inventory management and vastly improve your warehouse logistics, providing precise data for better decision-making. Solutions such as SKULabs can help reduce or even eliminate picking and packing errors saving you valuable time and money spent on customer service and the wrong items being shipped to customers.

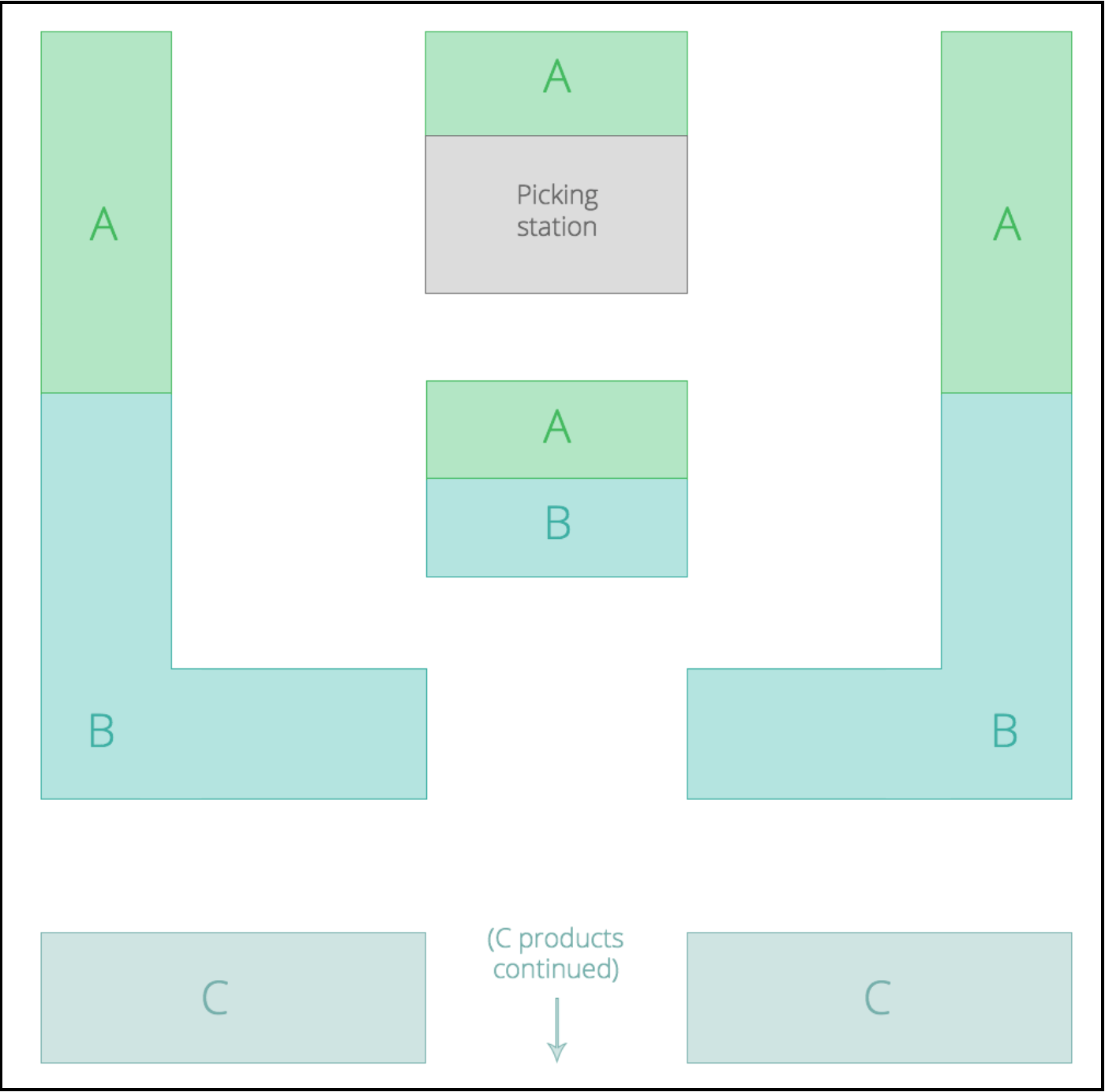

3. Picking and Packing Inefficiencies

Problem: Inefficient picking and packing processes can lead to slow order fulfillment, increased errors, and higher labor costs. This often stems from poor layout, inadequate staffing, or ineffective methods.

Solution: Optimize the warehouse layout with strategically placed items to minimize travel time. Utilize the ABC grouping methods to help optimize product placement in the warehouse closest to your packing stations. Additionally, with intelligent inventory management software such as SKULabs, you can implement zone picking, batch picking, or wave picking techniques suited to your operation’s size and nature. SKULabs lets you check each item to know whether it is an A, B, or a C categorized item. Regularly run this report to consistently optimize item placement in the warehouse. If budget allows, consider automation tools like conveyor belts, robots, or automated guided vehicles (AGVs) to speed up the process. Training staff regularly and employing ergonomic practices can also improve efficiency and accuracy.

4. Safety Hazards

Problem: Warehouses can be dangerous places with risks of accidents and injuries stemming from falls, equipment, or heavy lifting. Safety hazards can lead to employee downtime, legal issues, and costly compensation.

Solution: Conduct regular safety audits and training sessions to ensure all employees are aware of best practices and emergency procedures. Keep aisles clear, mark hazardous zones clearly, and maintain equipment regularly. Investing in safety equipment like proper lifting gear, non-slip mats, and guardrails can significantly reduce accidents and improve performance.

5. Labor Shortages and Turnover

Problem: Finding and retaining skilled warehouse staff is a challenge many facilities face. High turnover rates can lead to operational disruptions, increased training costs, and a decrease in overall productivity.

Solution: Offer competitive wages and benefits to attract and retain employees. Create a positive work environment with opportunities for growth and development. Regularly training and upskilling employees can improve job satisfaction and efficiency. Additionally, consider automation to reduce the strain on staff and cover for labor shortages. Solutions such as SKULabs helps keep your orders and inventory on track. Cycle counting in SKULabs takes the burden of the infamous yearly / monthly inventory away from the employees. It involves auditing a small subset of inventory items in the warehouse at specific intervals, maintaining accurate inventory levels. Rather than halting operations to count all items, companies adopt regular cycle counts. This approach promotes consistent accuracy while allowing day-to-day operations to proceed unhindered.

Implementing Solutions

Eliminating these common problems requires a proactive approach and continuous improvement. Here are general steps to implement these solutions effectively:

- Assess and Plan: Regularly evaluate your warehouse operations to identify areas for improvement. Develop a clear plan with specific, measurable goals.

- Invest in Technology: Leveraging modern technology like WMS, automated tools, and data analytics can significantly enhance efficiency and accuracy. Whether you are using a single or multi-warehouse operations, SKULabs can help ease the burden of automating most of your tasks.

- Train and Engage Staff: Ensure your team is well-trained and engaged. Their insights and cooperation are crucial for successful implementation.

- Monitor and Adjust: Continuously monitor performance against your goals. Be prepared to adjust your strategies as needed to address new challenges and opportunities.

Warehouse logistics are central to the success of many businesses. By understanding and addressing common problems like inefficient space utilization, inventory inaccuracy, picking and packing inefficiencies, safety hazards, and labor issues, you can significantly improve operations. Implementing the right solutions will not only enhance efficiency and safety but also contribute to better customer satisfaction and profitability. Remember, the key to overcoming these challenges lies in a strategic, integrated approach that involves technology, people, and continuous improvement.

Connect with SKULabs Today

Now is the perfect time to discuss how we can help you get prepared for taking your business to the next level!

Chat with one of our experts today. Schedule a meeting or give us a call at 1800-243-2986 to learn more.