SKULabs is committed to empowering businesses with innovative inventory management solutions that streamline their operations and help them thrive in the dynamic landscape of eCommerce. One of SKULabs’ primary goals is to ensure that its customers can maintain their workflow seamlessly, even when mandatory upgrades are introduced by marketplaces and storefronts.

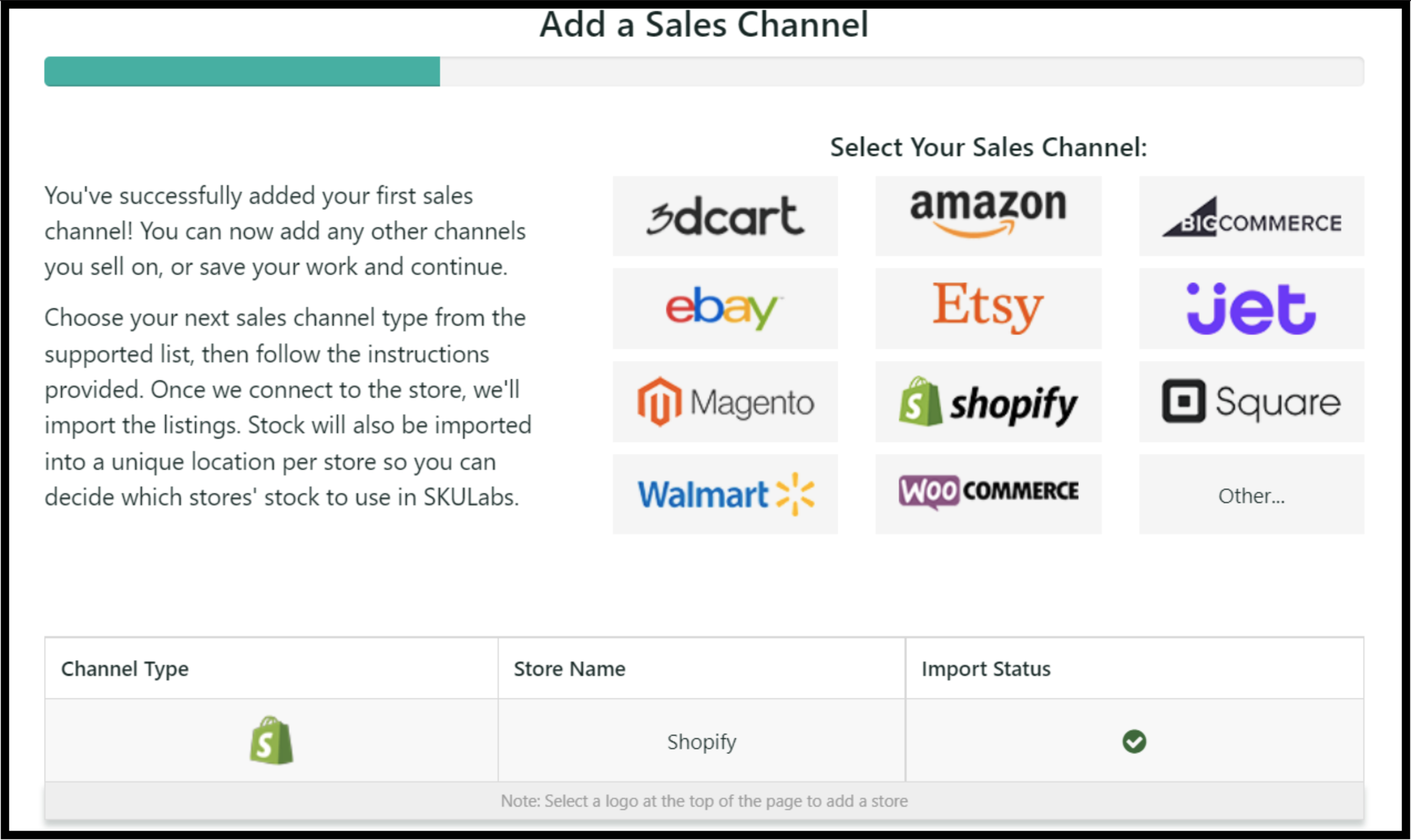

When major updates or migrations are implemented by platforms like eBay, Etsy, or Amazon, SKULabs actively steps in to provide a seamless transition process. This dedication ensures that businesses using SKULabs do not have to make any adjustments to their workflow or reconnect their stores from scratch.

For instance, when eBay implemented its order number migration, Etsy underwent a variant migration, and Amazon introduced the SP-API upgrade, SKULabs swiftly responded by offering a seamless transition process. This proactive approach allowed SKULabs’ customers to continue their operations without disruptions or the need to modify their workflow.

By taking on the responsibility of managing these transitions, SKULabs alleviates the burden on its customers and empowers them to focus on their core business activities. This commitment to maintaining workflow continuity sets SKULabs apart from its competitors, who may require their customers to reconnect their stores or make significant adjustments to their workflow during mandatory upgrades.

SKULabs’ unwavering dedication to minimizing disruptions during mandatory upgrades highlights its commitment to customer satisfaction and its understanding of the critical role that seamless operations play in the success of eCommerce businesses.

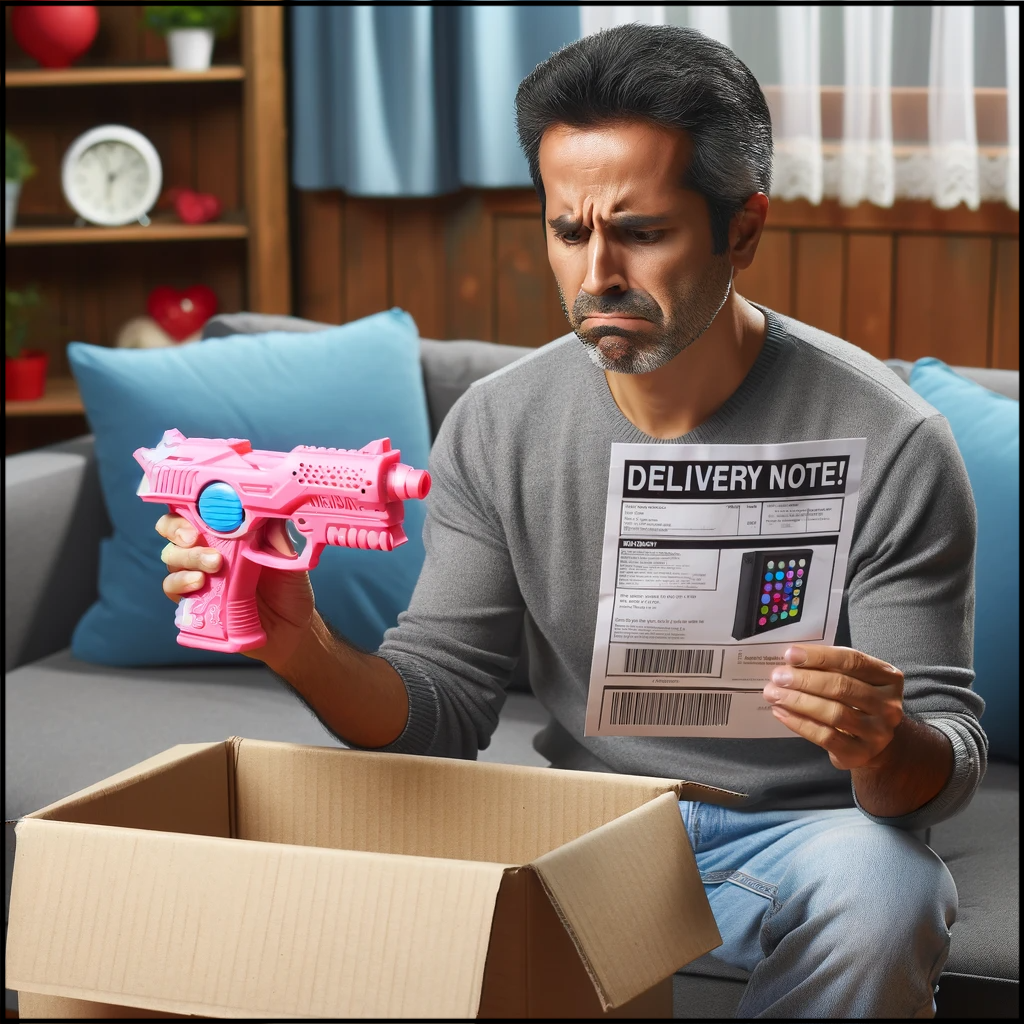

Migrate to Shopify Connector V2

This is the type of text you dread seeing in your inventory or order management solution. What are the negative impacts of this?

- Workflow disruption: Migrating integrations can disrupt your team’s workflow, requiring them to make changes to their processes.

- Data loss: There is a risk of data loss during the migration process where certain orders may be lost in between the two integrations.

- Data disconnection: It may be difficult or impossible to link reports seamlessly between the “old” and “new” integration.

- Downtime: The migration process can lead to downtime, which can prevent you from processing orders or managing inventory.

- Increased costs: Migrating integrations can be a costly process, especially if you need to hire a consultant or developer to help answer these unknown questions.

- Lost productivity: The time and effort required to migrate integrations can take away from your team’s productivity.

Automatic and seamless upgrades from SKULabs

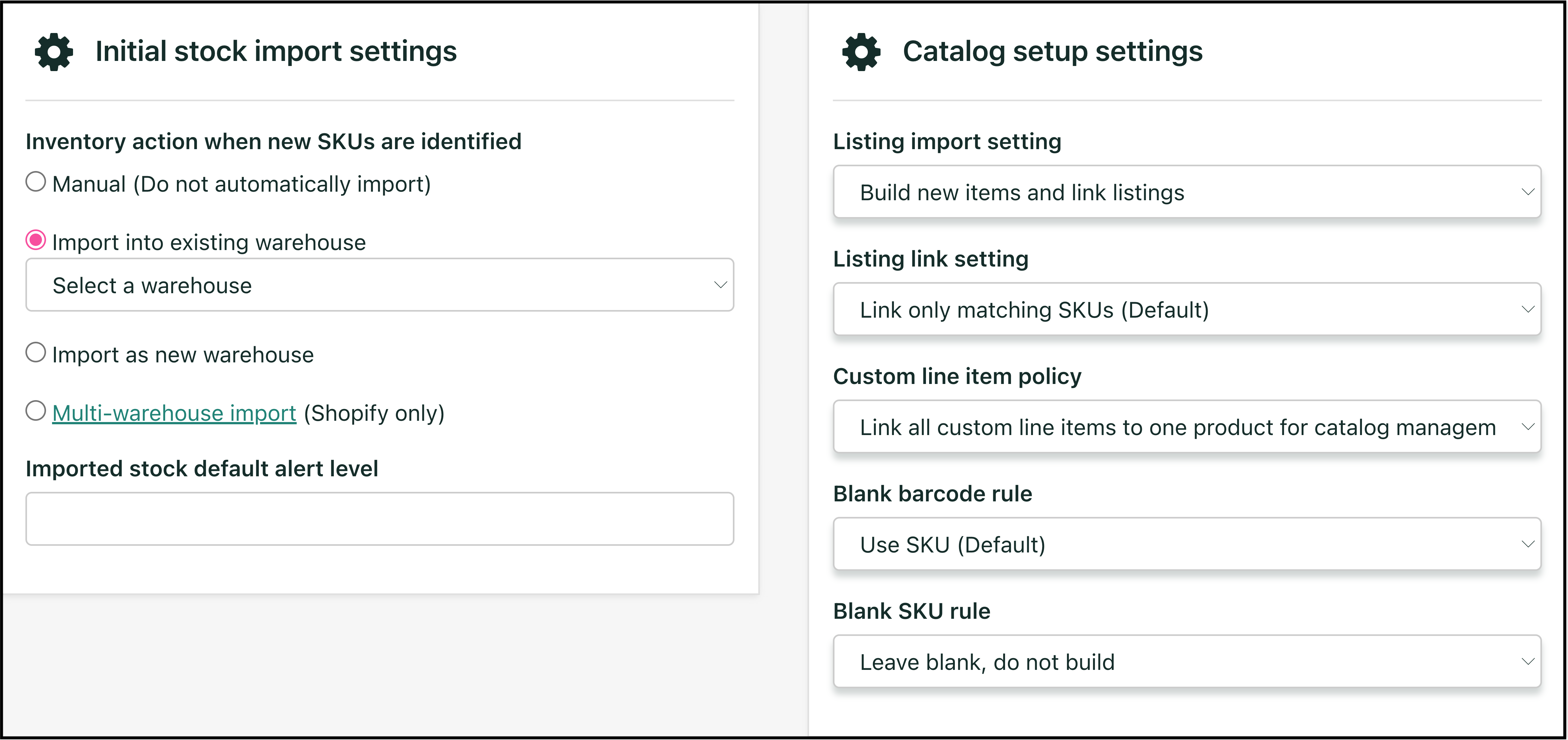

We are dedicated to making sure that our customers’ migrations between different platforms are seamless and effortless. Our team works tirelessly to ensure that your experience is as smooth as possible. We thoroughly test every major upgrade to make sure that there are no drastic changes or disruptions to your orders before and after the upgrade. While this process can sometimes be time-consuming and challenging, we actively collaborate with our partners like Shopify and Etsy to iron out any issues and deliver a seamless experience.

We have the resources and expertise to validate the impact of these upgrades, and we promptly notify our partners of any potential issues related to their upgrades. For example, we were recently at the forefront of resolving a major issue that affected the entire inventory and order management industry due to a significant Etsy variant ID upgrade. We were unable to work around this issue and provide a seamless transition through our platform. However, we promptly alerted Etsy and urged them to prioritize resolving this issue. This proactive approach helped reduce the potential pain and inconvenience that our customers would have faced when managing variants on Etsy.

Our commitment to providing a seamless migration experience sets us apart and ensures that our customers can focus on growing their business without worrying about technical challenges. We are constantly striving to improve our processes and work closely with our partners to deliver exceptional service.

Automatic recovery

At SKULabs, we prioritize the reactivity of our integrations to their environment, ensuring seamless and efficient synchronization processes. Our integrations are equipped with exponential fallback algorithms that automatically detect, cancel, restart, and recover from incidents affecting sync. This approach allows us to avoid continuous attempts to access unavailable servers while minimizing unnecessary delays.

Internally, our team is alerted when a specific number of stores are impacted by an outage. We possess robust capabilities to identify the root cause of outages, whether at the store, provider, marketplace, or even at the internet scale (e.g., AWS or CloudFlare). In the event that a release is related to an outage, we promptly initiate a rollback and mitigate the impact within minutes.

This proactive approach enables us to maintain the integrity and reliability of our integrations, minimizing disruptions to our customers’ operations. We continuously monitor and optimize our systems to further enhance their resilience and ensure uninterrupted sync processes. By leveraging advanced algorithms and robust monitoring mechanisms, we strive to provide our customers with a seamless and reliable integration experience.

Multiple modes of sync

When many integration platforms claim to connect to Shopify, they frequently rely on a time-consuming and significantly delayed inefficient use of the API to pull orders that can take several hours to complete. In contrast, SKULabs employs a multi-lane approach to tracking orders, with each lane having a unique cadence. This unique optimization strategy ensures maximum efficiency and meets the specific needs of each e-commerce channel.

Our Etsy integration stands out as a prime example of this approach. We have meticulously optimized our utilization of Etsy’s limited rate limits to support the maximum possible number of orders and variants. This optimization allows us to seamlessly handle even the largest Etsy stores in the industry.

On the other hand, our Shopify sync is capable of importing thousands of orders in a matter of seconds. This rapid import ensures that we are always importing the most recently changed orders as quickly as possible.

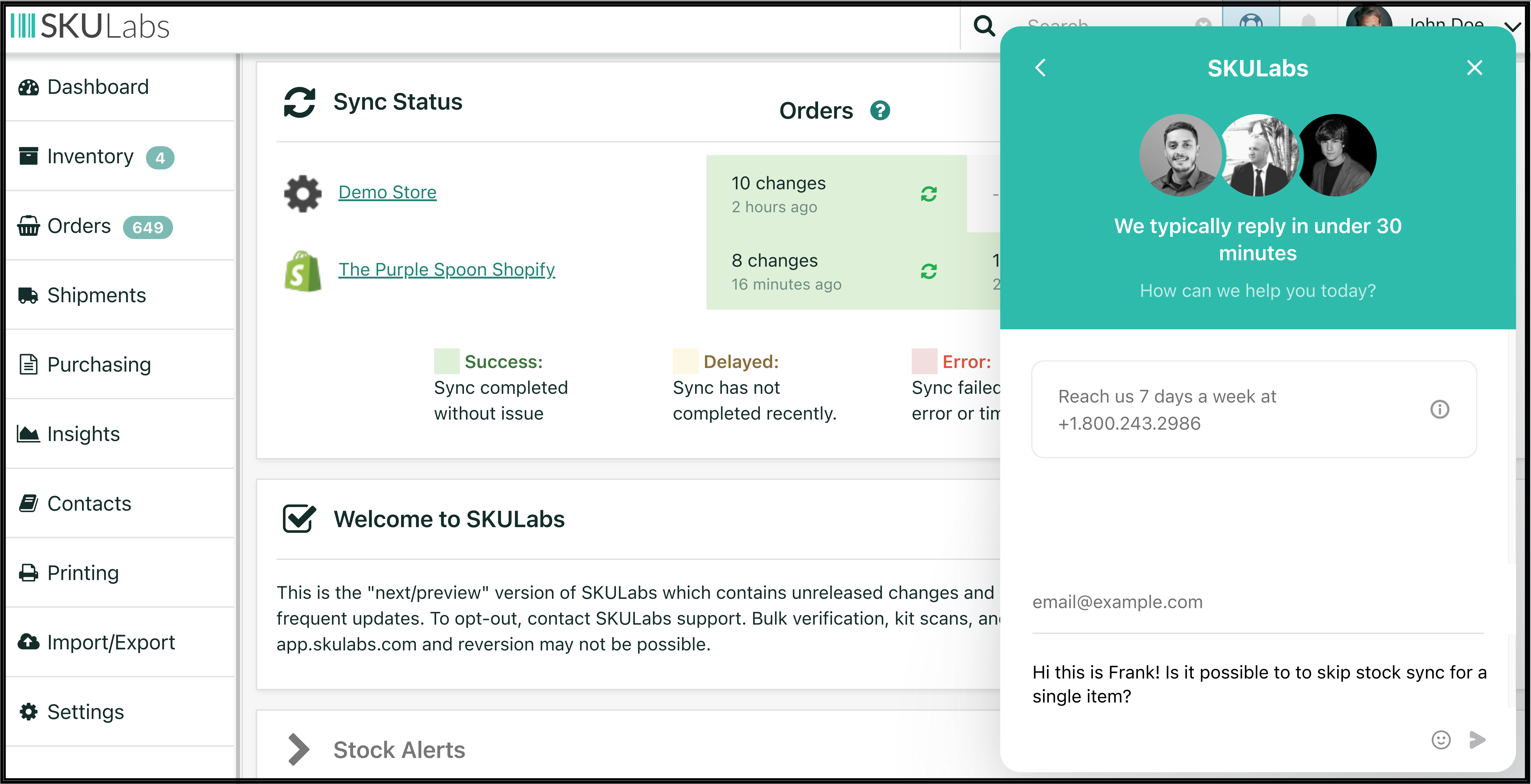

Moreover, SKULabs provides an in-app order log that transparently displays the time it took for your sales channel to process the order and the time it took to import it into our system. This detailed information helps you and our team effectively measure performance over time and promptly identify any payment processing or other performance issues.

By leveraging our multi-lane approach and optimizing integrations for specific platforms, SKULabs delivers fast, reliable, and scalable order tracking solutions that empower e-commerce businesses to operate seamlessly and efficiently.

Do you have a unique challenge with sync? We would love to hear about it at support@skulabs.com